Toolroom Grinding Wheel

Toolroom Grinding Wheel Specification

- Bonding

- Vitrified, Resin bond

- Backing

- None

- Grain Type

- White, Brown, Green, Black

- Shape

- Straight, Cylindrical, Dish, Cup

- Chemical Composition

- Al2O3, SiC, bonding agents

- Toughness

- High fracture toughness

- Hardness

- Soft, Medium, Hard

- Material

- Aluminum Oxide, Silicon Carbide

- Type

- Toolroom Grinding Wheel

- Grain Sizes

- Fine, Medium, Coarse (24 to 120 grit)

- Rolls Size

- 6 inch, 8 inch, 10 inch, 12 inch (custom sizes available)

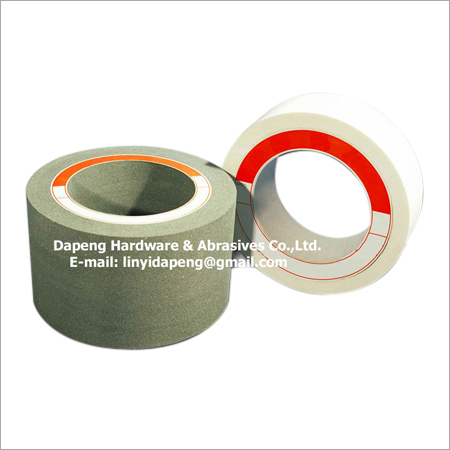

About Toolroom Grinding Wheel

Our enterprise has gained immense recognition in manufacturing, exporting and supplying a quality assured array of Cup Wheel. Offered wheel is widely used for sharpening milling-cutter, reamers, expanding drills, broaches, paper cutting knifes, knifes, etc. This wheel is manufactured by making use of excellent grade raw materials and advanced technology in line with set industry standards. Clients can avail this Cup Wheel from us at rock bottom prices.

Key Features:

- Abrasion resistance

- High strength

- Impeccable finish

- Enhanced durability

Specification:

Popular Size

100 x 50 x 31.75mm

B 13,B 13

125 x 100 x 31.75mm

B 13, B 13

150 x 100 x 31.75mm

B 20, B 20

200 x 100 x 31.75mm

B 25, B 25

Grit Size: 36#,46#,60#,80#,100#,120#,240#....

Materials: A (brown aluminum oxide), WA (white aluminum oxide), PA (pink aluminum oxide), GC (green silicon carbide), C (black silicon carbide)

They also can be supplied in required sizes,materials, grit sizes and types.

Versatile Sizes and Shapes

Our toolroom grinding wheels are offered in standard diameters of 6, 8, 10, and 12 inches, with custom sizes available to meet specialized requirements. Select from straight, cylindrical, dish, or cup shapes to accommodate diverse grinding applications and machinery.

Advanced Material Selection

Constructed from high-quality aluminum oxide and silicon carbide, these wheels provide efficient abrasive action and durability. Both vitrified and resin bonding ensure proper grain retention, while color-coded grainswhite, brown, green, or blackallow easy identification and suitability for different workpieces.

Performance Across Applications

Ideal for grinding, shaping, and sharpening toolroom parts, our wheels deliver consistent results in both coarse material removal and fine finishing. They feature customizable grain sizes (24-120 grit), as well as variable hardness for soft, medium, or hard grinding needs.

FAQs of Toolroom Grinding Wheel:

Q: How do I select the right toolroom grinding wheel size for my machinery?

A: Choose the wheel diameter (6, 8, 10, or 12 inches) based on your machines compatibility and the scale of your grinding task. Custom sizes are available if your requirements fall outside standard options.Q: What are the main material options and their benefits in these grinding wheels?

A: We offer grinding wheels made from aluminum oxide (Al2O3) and silicon carbide (SiC). Aluminum oxide is ideal for general-purpose grinding of steel, while silicon carbide is recommended for non-ferrous metals and carbide tools. Both provide excellent durability and performance.Q: When should I use coarse versus fine grain sizes in grinding?

A: Use coarser grits (2460) for heavy material removal or rough shaping, and finer grits (80120) for achieving smooth surface finishes or delicate precision work. Match the grain to your desired surface quality and material type.Q: Where are these toolroom grinding wheels typically used?

A: These wheels are essential in toolrooms, manufacturing plants, and workshops where precision grinding, sharpening, and finishing of tools and components are performed, accommodating a wide range of machines and projects.Q: What bonding options are available and how do they affect performance?

A: Wheels are available in vitrified or resin bonds. Vitrified bonds provide rigidity and longevity, suitable for high-speed or precision applications. Resin bonds offer more flexibility and resistance to thermal shock, aiding rapid material removal.Q: How does the wheels hardness and toughness impact usage?

A: Choosing the appropriate hardness (soft, medium, hard) is key: softer bonds release worn grains quickly for faster cutting, while harder bonds hold grains for longevity. High fracture toughness ensures the wheel withstands demanding applications without breaking down prematurely.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Grinding Wheels Category

Ball Grinding Wheel

Minimum Order Quantity : 3 Pieces

Shape : Round

Hardness : Hard

Type : Ball Grinding Wheel

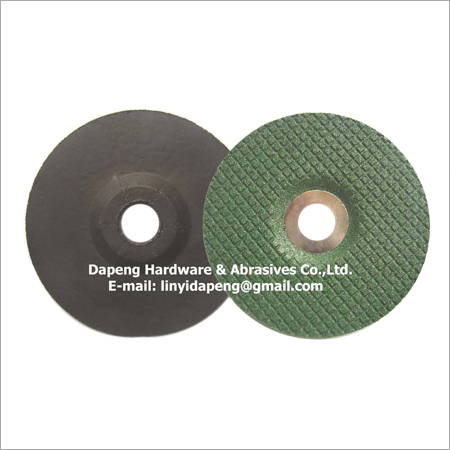

Flexible Grinding Wheel

Minimum Order Quantity : 50 Pieces

Shape : Round

Hardness : Yes

Type : Flexible Grinding Wheel

Material : SS

Regulating Grinding Wheels

Shape : Round

Hardness : Soft to Medium

Type : Regulating Grinding Wheel

Material : Aluminium Oxide / Silicon Carbide

Grain Type : Coarse / Fine

Centerless Grinding Wheels

Shape : Round / Wheel

Hardness : From N (Medium) to R (Hard)

Type : Centerless Grinding Wheel

Material : Abrasive Grain + Bonded Matrix

Grain Type : Aluminium Oxide / Silicon Carbide

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry